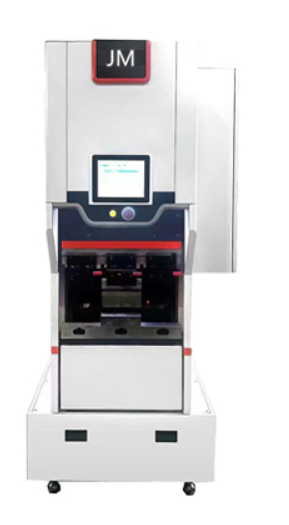

CNC bending machine

Superior Stability and Rigidity: The CNC bending machine features an integral welded bed made of steel plate, offering excellent shock resistance and rigidity.

Stress-Free Frame: The annealing process eliminates stress in the frame, ensuring high stability and preventing deformation.

Energy Efficient and Low Noise: Delivers excellent energy-saving performance, operates at high speed with low noise.

User-Friendly Interface: The automatic bending process interface is simple and easy to learn, reducing the need for extensive operator training.

Automatic Angle Compensation: The machine automatically calculates and compensates for bending angles, ensuring precise results with minimal trial bends.

Product Introduction

The CNC bending machine is designed for high-performance, precision bending of sheet metal. Featuring a steel plate welded bed, it offers superior rigidity and shock resistance, ensuring long-lasting stability. The annealing process eliminates stress and prevents deforThe CNC bending machine precisely controls the movement of mechanical parts through the digital control system (CNC) to achieve the bending operation of metal sheets. working process is generally as follows: place the metal sheet on the workbench, input the bending angle, length and other parameters through the CNC system, and the control drives the hydraulic or motor drive system according to these parameters, so that the slide block drives the mold to move downward, applying pressure to the sheet, so that ites plastic deformation under the action of the mold, thus achieving the desired bending shape and angle.mation, making the machine reliable for heavy-duty operations. With excellent energy efficiency, fast processing speeds, and low noise output, it provides an efficient solution for modern manufacturing needs. Its simple interface and advanced bending technology allow for easy operation, while automatic angle compensation and back gauge calculations enhance precision and productivity.

Specifications

model: 35-1250

Controlled Axes: Y1 、Y2、 X、 R、 Z1、 Z2

Dimensions (mm)(length * width * height): 1350*1260*2150

Workbench length(mm): 1250

Bending pressure(KN): 350

Applications

Sheet metal processing industry: It is widely used in the production of various sheet metal products, such as distribution boxes, boxes, cabinets, ventilations, etc. It can quickly and accurately complete various shapes and sizes of sheet metal bending tasks, improving the quality and efficiency of sheet metal processing.

Automobile manufacturing: It is used for the processing of automobile body structure parts, chassis parts, interior parts, etc. For example, the bending processing of automobile doors, engine h, frames and other parts has extremely high requirements for precision and quality, and CNC bending machines can well meet these requirements, ensuring the assembly precision and safety of automobile parts